Introduction:

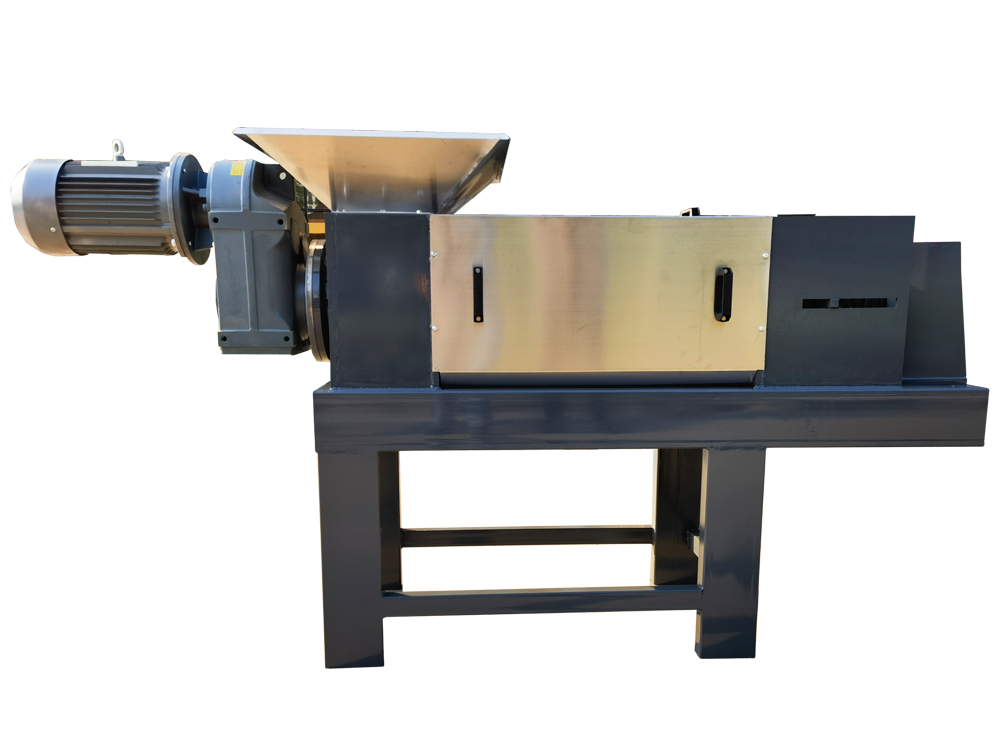

In the pursuit of sustainable waste management practices, the organic waste screw press dehydrator machine has emerged as a groundbreaking solution. This innovative technology addresses the environmental challenges associated with organic garbage disposal by efficiently reducing the volume of waste and producing valuable by-products.

Key Features:

High Efficiency Dehydration:

The organic waste screw press dehydrator machine employs a robust screw mechanism to effectively extract moisture from organic waste materials. This results in a significant reduction in the volume of the waste, making it easier to handle and transport.

Versatility in Waste Processing:

Designed to handle various types of organic waste, including kitchen scraps, food waste, and agricultural residues, this machine provides a versatile solution for waste management across different industries.

Energy-Efficient Operation:

With a focus on sustainability, these dehydrator machines are engineered to operate with minimal energy consumption. The efficient dehydration process contributes to lower energy requirements, aligning with eco-friendly practices.

Production of Nutrient-Rich By-Products:

The residual material extracted from the organic waste contains concentrated nutrients, making it an ideal fertilizer. This by-product can be utilized in agriculture to enhance soil fertility and promote sustainable farming practices.

Compact Design and Space Efficiency:

The compact design of the screw press dehydrator allows for easy installation and integration into existing waste management systems. Its space-efficient footprint makes it suitable for both large-scale industrial facilities and smaller community setups.

Benefits:

Waste Volume Reduction:

By significantly reducing the volume of organic waste, the screw press dehydrator contributes to more efficient waste disposal and minimizes the need for extensive landfill space.

Odor Control:

The dehydration process helps control and mitigate the foul odors often associated with decomposing organic waste, creating a more pleasant and hygienic environment.

Cost Savings:

The production of nutrient-rich by-products reduces the need for external fertilizers in agriculture, leading to cost savings for farmers. Additionally, the decreased waste volume results in lower transportation and landfill disposal costs.

Environmental Conservation:

Implementing organic waste screw press dehydrator machines aligns with global efforts to reduce environmental impact. By diverting organic waste from landfills, it helps decrease methane emissions and contributes to a more sustainable and circular economy.

Conclusion:

The organic waste screw press dehydrator machine represents a sustainable and efficient solution for managing organic garbage. With its high dehydration efficiency, versatility, and environmental benefits, this technology is playing a crucial role in transforming waste management practices towards a more sustainable future.

TEL:+86 15336363999

TEL:+86 15336363999

WeChat:gongchris1111

WeChat:gongchris1111

ADD:Fangzi District, Weifang City, Shandong Province, China

ADD:Fangzi District, Weifang City, Shandong Province, China